Aluminum Framing Solutions

At Pacific Integrated Handling (PIH), we believe that the right solution is more than just the right product. It is the right partner behind it. Since 1995, we have been helping manufacturers, engineers, and industry leaders across the Pacific Northwest and beyond find smarter, more efficient ways to build and optimize their operations.

Our aluminum structural framing systems, powered by Bosch Rexroth, are one of the many tools we use to help customers streamline their facilities. But what sets PIH apart is not just the framing itself. It is how we apply it. We do not just deliver components. We deliver complete engineered solutions, hands on support, and the experience to help your business grow.

Bosch Rexroth and PIH

As an authorized Bosch Rexroth partner, PIH gives you access to one of the most advanced aluminum framing systems in the world. Our team’s local expertise, industry knowledge, and problem-solving approach turn those components into practical solutions for your operations.

This partnership combines the reliability of a global leader with the personalized service of a local team that understands your business.

Inventory & Support

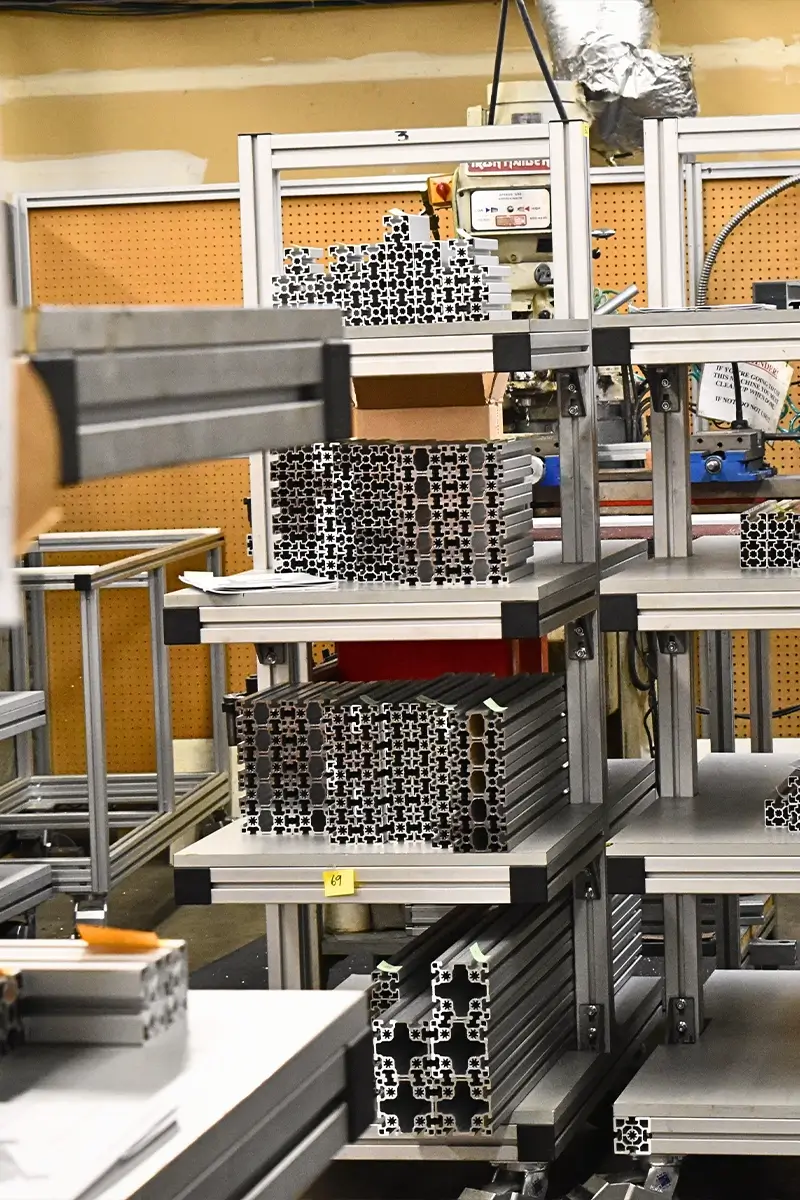

PIH is North America’s largest stocking distributor of Bosch Aluminum framing, with extensive inventory at our Tacoma, WA, and Dallas, TX locations. From profiles and connectors to fasteners and panels, we keep the critical parts you need in stock so your projects never stall.

Our experts make it easy to select the right components, design smarter solutions, and avoid delays. Flexible delivery options including bulk shipments, pre-kitted solutions, or fully assembled structures ensure your project keeps moving.

With sales and service coverage across the Western U.S. (WA, OR, ID, MT, CA, AZ, NM, NV, UT, TX, OK, AK, & LA), PIH provides local availability, proven expertise, and a partner committed to your success.

Design & Engineering

The PIH CAD Engineering Team works in Inventor 3D to verify the fit, form, and function of each buildable design. Our staff of four full-time designers are ready to assist in documenting your project, ensuring accuracy from the first concept through to the final build.

We use advanced CAD tools to create detailed 3D models, streamline documentation, and support a wide range of file formats, including STP, IGES, SolidWorks, and CATIA. Our team can also convert client CAD files directly, making collaboration simple and efficient.

Good design reduces material waste, shortens production times, and improves cost-efficiency. By working closely with our clients, we ensure every solution is tailored to their needs. With rapid prototyping, we can quickly move from concept to production, delivering high-quality results with precision and speed.

From conception to build, PIH design services provide the accuracy, efficiency, and support you need to bring your project to life.

Raw Materials, Kitted Solutions & Custom Assemblies

As a Bosch Rexroth Certified Excellence Assembly Technology distributor, PIH is able to provide raw materials, kitted solutions and custom assemblies from both manufacturing locations. We have 30 years of experience and proven solutions, making PIH the most experienced team around. Our processes have been continually updated to better serve our customer base with Inventor detailed build designs, state of the art cutting, cleaning, packing and assembly processes to ensure a perfect fit.

The Extra Mile

At PIH, we believe our job is not finished until our customers are fully satisfied. That commitment is why we have built capabilities that go beyond standard distribution. Our in-house CNC shop produces short-run custom parts to meet the unique demands of complex assemblies. We partner with trusted controls and automation teams to deliver turnkey automation solutions, ensuring our systems are as intelligent as they are strong.

To further support our customers, PIH offers in-house Factory Acceptance Testing (FAT) as well as on-site assembly and services. And with customer service teams operating across three time zones, you can count on responsive support whenever and wherever you need it.