Introduction

Cleanrooms are controlled environments that minimize airborne particles, contaminants, and pollutants. They are critical in industries such as medical, semiconductor, aerospace, biotechnology, and food production. To maintain high cleanliness levels, every part of the cleanroom must be carefully selected-and aluminum framing plays a key role, providing strength, flexibility, and easy maintenance. Below, we explore how aluminum framing supports cleanroom construction, with a focus on its benefits and applications.

What is a Cleanroom?

A cleanroom is a space where factors like temperature, humidity, and air purity are controlled to ensure product quality. They are classified by the number of particles allowed per cubic meter of air, with ratings such as ISO 5, ISO 7, and ISO 8.

Even particles can disrupt production, cause defects, or affect research. making air filtration essential. Cleanrooms use HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Particulate Air) filters to maintain air quality.

Why Aluminum Framing is Ideal for Cleanrooms

Aluminum framing offers many advantages for cleanroom construction. Here’s why it stands out:

Lightweight but Strong: Aluminum is easy to transport and install, without compromising on durability.

Resistant to Corrosion: Aluminum’s natural oxide layer protects it from rust, ensuring a long lifespan.

Easy to Clean: It’s smooth, non-porous surface prevents dust buildup and simplifies disinfection.

Modular Design for Flexibility: Aluminum frames make it easy to reconfigure or expand cleanrooms as needed.

Electromagnetic Interference (EMI) Shielding: Aluminum provides EMI shielding, important for precision equipment in industries like aerospace.

Key Applications of Aluminum Framing in Cleanrooms

Workstations and Benches: Used for precision tasks like assembly, testing, and repair. Shelves and drawers can easily be added to improve workflow.

Barriers and Enclosures: Aluminum frames are ideal for lightweight walls and enclosures made from polycarbonate or acrylic panels, which prevent contamination and are easy to clean.

Carts and Material Handling: Aluminum-framed carts are lightweight, corrosion-resistant, and easy to clean-ideal for moving materials in sterile environments.

Platforms and Guardrails: Aluminum platforms give workers access to elevated areas while ensuring safety and ergonomic design.

Equipment Enclosures: Precision tools often need protective environments. Aluminum enclosures shield equipment from contamination.

How Aluminum Framing Supports Cleanroom Design

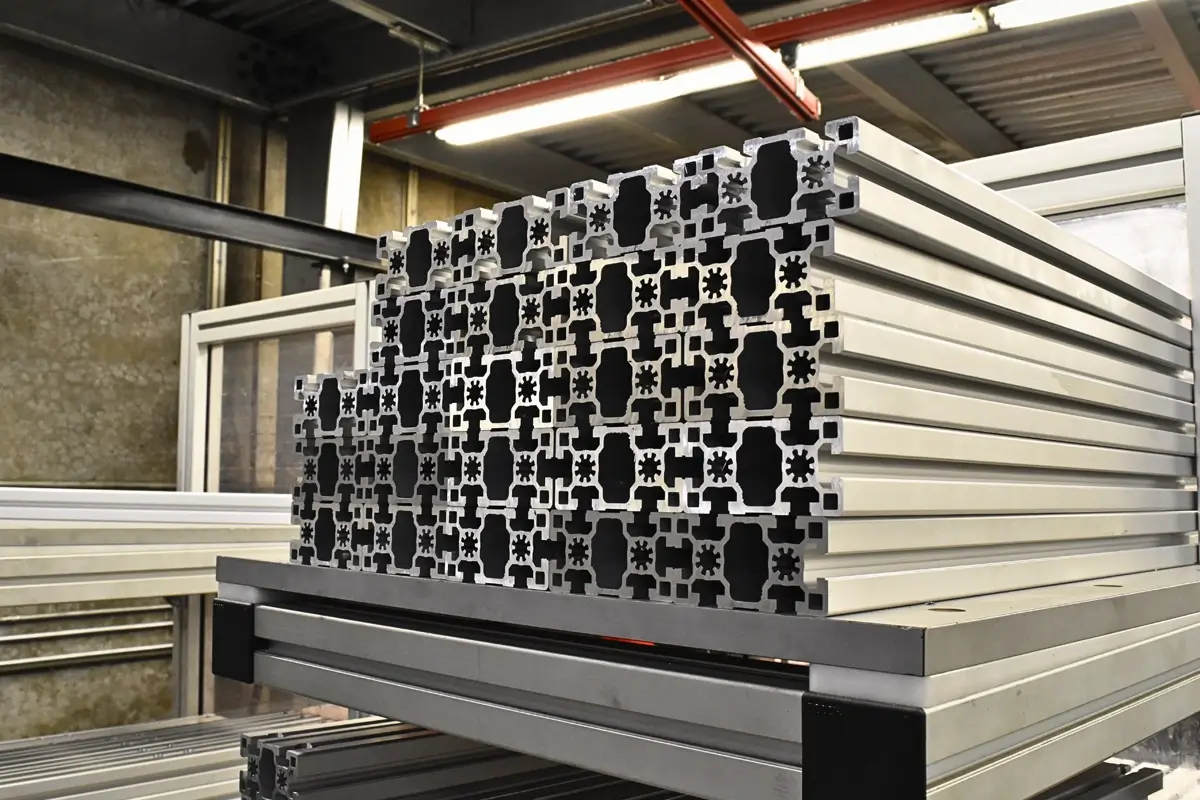

Modula Panels for Quick Assembly: Cleanrooms often use pre-engineered aluminum panels that are easy to install and rearrange. Panels can be made form acrylic, glass, or polycarbonate, giving flexibility in design.

Integrated Ceiling and Floor Systems: Aluminum Framing can connect seamlessly with vinyl or epoxy floors. Ceilings grids made from aluminum can house HEPA filters, lights, and sprinklers.

Utility Integration: One of the biggest advantages of aluminum framing is the ability to route wires, air ducts, and data cables through the structure. This keeps the environment organized while ensuring equipment stays connected.

Lean Production Benefits of Aluminum Framing

Modern industries prioritize lean production principles, such as eliminating waste and maximizing efficiency. Aluminum framing supports these efforts by:

Modula Panels for Quick Assembly: Cleanrooms often use pre-engineered aluminum panels that are easy to install and rearrange. Panels can be made form acrylic, glass, or polycarbonate, giving flexibility in design.

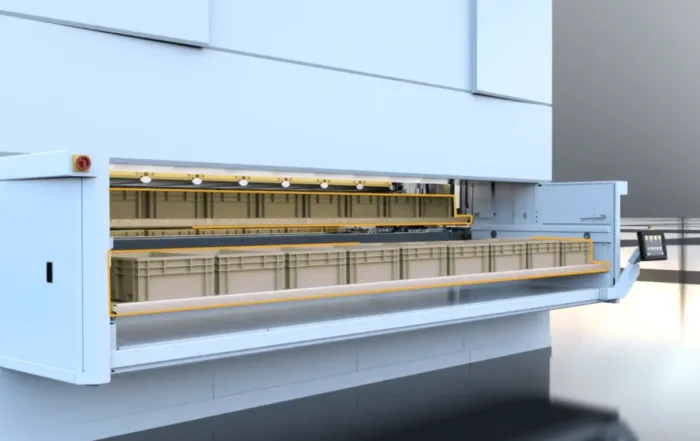

Minimized Downtime: With modular systems, you can make adjustments without interrupting operations, saving time and money.

Custom Workflow Design: Workstations and storage systems can be built to match specific workflows, making production smoother and more efficient.

Sustainability: Aluminum is recyclable, so cleanroom construction and maintenance have a reduced environmental footprint.

Sustainability Benefits of Aluminum Framing

Recyclability: Aluminum can be recycled indefinitely without losing strength or quality, making it an eco-friendly option for cleanroom construction.

Energy Efficiency: Because aluminum is lightweight, less energy is required for transportation and installation. Its modular design also optimized airflow, helping HVAC systems work more efficiently.

Industry Standards for Cleanrooms

To ensure cleanrooms meet strict cleanliness and safety standards, they must comply with:

ISO 14644: Defines the cleanliness levels required for cleanroom air quality.

cGMP Compliance: Ensures pharmaceutical production follows Good Manufacturing Practices to maintain product safety and quality.

FDA and EU Regulations: Establish guidelines for cleanrooms used in food and medical industries.

Aluminum framing systems are built to meet these standards, ensuring cleanrooms stay compliant and operational.

Common Challenges with Aluminum Framing

Temperature Sensitivity: Aluminum conducts heat, which could affect some temperature-sensitive processes. Adding insulating panels can help manage this issue.

Static Buildup (ESD Risks): Cleanrooms that handle electronics must control static discharge. Aluminum frames can be coated with ESD-safe materials or connected to a grounding system to prevent static buildup.

Sealing for Contamination Control: Proper sealing prevents leaks or contamination. Using gaskets and airtight seals ensures cleanroom integrity.

Conclusion

Aluminum Framing is an essential component in modern cleanroom construction, offering strength, flexibility, easy maintenance, and corrosion resistance. Its modular design allows companies to modify and expand cleanrooms as needed, while its smooth surface makes it easy to clean and maintains strict hygiene standards. With benefits like EMI shielding, recyclability, and energy efficiency, aluminum framing ensures cleanrooms meet both industry standards and environmental goals.

If you’re ready to build or upgrade a cleanroom with modular aluminum framing systems, Pacific Integrated Handling offers tailored solutions that meet your specific needs. Whether you’re in medical, aerospace, or semiconductor, we can help you design cleanrooms that boost efficiency and maintain compliance. Be sure to sure checkout out our Cleanroom Application Catalog to explore our full range of solutions and see how we can support your next project.