Modula’s Vertical Lift Modules (VLMs) Are Changing the Aerospace Industry

These are not ordinary storage units; they revolutionize organizing, accessing, and managing aerospace components. Thanks to their smart automation and great use of space, VLMs are changing our approach to aerospace storage. They are setting new standards for efficiency and reliability.

Introduction

Transform Your Operations with Modula VLMs

In the ever-changing world of aerospace, the search for better efficiency and accuracy never stops. As the industry grows, embracing new technologies and methods is not just helpful – it’s critical. Amidst this constant change, storage is one area that greatly affects efficiency but often remains overlooked. This is especially true in aerospace, where handling a wide range of parts, from very small to very large, is an everyday task.

Here comes the breakthrough solution: Modula Vertical Storage Modules (VLMs). These are not ordinary storage units; they revolutionize organizing, accessing, and managing aerospace components. Thanks to their smart automation and great use of space, VLMs are changing our approach to aerospace storage. They are setting new standards for efficiency and reliability.

In the following sections, we’ll look at how VLMs are changing aerospace storage and logistics. We’ll see how they help us reach amazing levels of efficiency and productivity.

Industry Challenges & VLM Solutions

The aerospace industry is complex and always changing, with a huge need for technical know-how and smart logistics. Storing various parts correctly is a major challenge in this field, from tiny, delicate electronics to huge aircraft pieces. Traditional storage methods often fall short in aerospace because they don’t save enough space, allow quick access to parts, or adhere to strict safety standards.

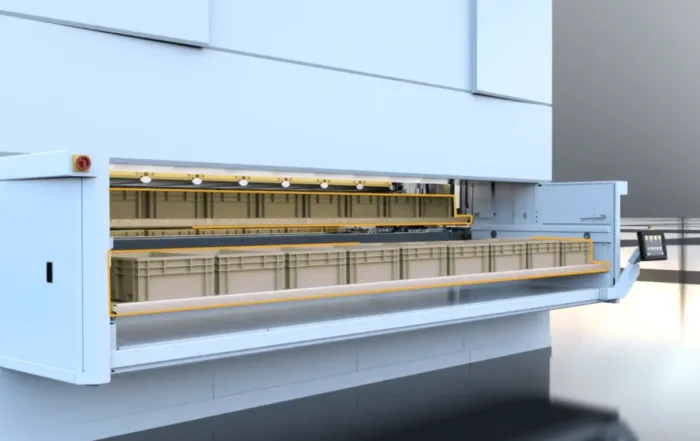

Enter Modula Vertical Lift Modules (VLMs), a game-changing solution. These systems make the most of vertical space, which is valuable in crowded areas like hangars and factories. But it’s not just about saving space. It’s about making every inch work harder and smarter.

What’s more, VLMs bring automation into the mix, making everything run more smoothly. They can find and retrieve parts fast, saving precious time and, therefore, money. This kind of automation also means better record-keeping and less chance of losing things.

By tackling major storage issues, Modula VLMs are changing aerospace. They simplify, speed up, and secure the storage of various parts and tools. Integrating Modula VLMs into aerospace environments greatly improves space use, efficiency, and technological adaptation — all essential for leading in this rapidly advancing field.

In summary, Modula VLMs are not just organizing space — they’re entirely reshaping aerospace storage, meeting the modern demands for precision and efficiency.

Saving Money & Working Smarter

In the high-stakes, competitive world of aerospace, companies are always looking for ways to save money without losing quality or efficiency. Modula Vertical Lift Modules (VLMs) are key here. They help save a lot of money and improve operations, which is essential for success in the aerospace industry.

A major advantage of Modula VLMs is the big cut in labor costs. Traditional storage often needs a lot of manual work to manage and find inventory, which takes time and can lead to mistakes. VLMs solve this by automating these tasks, making the retrieval of parts and tools faster and more accurate. This means less time spent on inventory, which can save a lot of money.

Also, VLMs use vertical space well, which is great for aerospace facilities where space is limited. This efficient use of space means companies can store more in a smaller area, avoiding the costs of expanding or renting more space.

Plus, VLMs help avoid mistakes when picking items. In aerospace, a small error can be very costly. The accuracy of VLMs saves money by reducing these errors and makes operations run smoother, boosting productivity.

These benefits are real – many aerospace companies have seen big improvements in their storage and efficiency, all thanks to Modula VLMs.

Technological Innovations & Integration

Modula Vertical Lift Modules (VLMs) bring modern technology to aerospace storage. They improve how VLMs work and easily fit with current systems, offering a smart and effective way to keep things organized.

A main feature of these VLMs is their advanced control panel and user-friendly interface. They come with digital screens and easy-to-use software, making it simple to manage inventory. Operators can quickly find and manage items using touchscreen and barcode scanning, which helps cut down on time and mistakes.

Also, Modula VLMs work well with existing Warehouse Management Systems (WMS). This means they can smoothly share information and track inventory in real time, thus making everything more reliable and efficient without altering existing processes.

You can tailor these VLMs to meet various aerospace needs, from tiny, fragile pieces to large, heavy parts. This flexibility is crucial for meeting the aerospace industry’s diverse storage requirements.

Overall, Modula VLMs are not just about storing items. They are a step up in making operations more efficient and precise, designed for today’s aerospace industry needs.

Case Studies & Success Stories

We see the real value of new technology in its application and the benefits it offers. Modula Vertical Lift Modules (VLMs) have made a big difference for many aerospace companies, showing how effective they can be.

Success Story of Safran with Modula VLMs: Safran, a top company specializing in aircraft engine maintenance, had to manage a large inventory in a small space. By using seven Modula VLMs, Safran saw impressive results:

GE Celma’s Improvement with VLMs: GE Celma, a leading aircraft engine maintenance facility in Latin America and part of GE Aerospace, faced challenges with space and safe storage. Installing six Modula VLMs resulted in:

These examples show how Modula VLMs have greatly improved efficiency, space use, and inventory management in the aerospace sector. Their success stories highlight the significant changes these storage solutions can bring.

Compliance with Aerospace Standards

In the aerospace industry, following strict standards and rules is essential for working excellence and safety. Modula Vertical Lift Modules (VLMs) are crucial in helping aerospace companies meet these demanding standards.

The International Aerospace Quality Group (IAQG) set up the AS9145 standard to guide suppliers in aviation, space, and defense. This standard includes steps for Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP), important for meeting strict production and regulatory requirements.

Modula VLMs help with important parts of the AS9145 standard. They improve the storage, organization, and access to prototype parts, molds, tooling, and materials during product development stages. This helps keep materials for different projects separate, safe, and easy to find.

During the PPAP stage, where suppliers show they can consistently produce parts to a customer’s specifications, Modula VLMs enhance the ability to store and find production materials and parts. Their precise inventory management is crucial for maintaining quality and preventing mistakes, which are key to ensuring product quality.

By using Modula VLMs, aerospace companies can greatly improve their adherence to industry standards like AS9145, making sure they meet and even surpass the high quality and safety standards expected in the industry.

Conclusion

We’ve seen how Modula’s Vertical Lift Modules (VLMs) are changing storage in the Aerospace industry. These systems are more than just solutions; they mark a big step forward. VLMs bring unmatched efficiency, accuracy, and flexibility, setting new benchmarks in aerospace logistics and storage.

If you’re an aerospace professional looking to better your storage, boost efficiency, and stick to tough standards, you should consider Modula VLMs. They save space, reduce costs, bring in new technology, and ensure high quality. Overall, they offer a complete solution for the needs of the aerospace industry.

If you’re ready to transform your operations with Modula VLMs, our team at Pacific Integrated Handling is here to help. For more details, expert advice, or to get a quote, please contact us directly through this website. Let us assist you in achieving unmatched efficiency and productivity in your aerospace storage.