Washington Aerospace Training & Research Center (WATR)

The custom training workstations led to a significant increase in student throughput in WATR's programs, resulting in increased revenue for the center. The upgrades improved ergonomics, safety, and precision, aligning the training facilities with modern industry standards.

Introduction

WATR Encountered Several Challenges

The Washington Aerospace Training & Research Center (WATR), a premier institute in aerospace manufacturing and assembly training, faced significant challenges in aligning their training facilities with Boeing’s modern standards. They required innovative solutions to upgrade their training stations, enhance ergonomics, and integrate the latest technologies. With objectives focused on improving safety, precision, and efficiency, WATR turned to us for a customized solution.

Client Background

Located in Everett, WA, the Washington Aerospace Training & Research Center specializes in aerospace manufacturing and assembly training. The center is dedicated to advancing the aerospace sector through rigorous training and state-of-the-art facilities, preparing students and professionals to meet the industry’s complex and evolving needs. WATR emphasizes practical skills and real-world applications, playing a crucial role in cultivating the next generation of aerospace professionals.

Challenges Faced

WATR encountered several challenges, including:

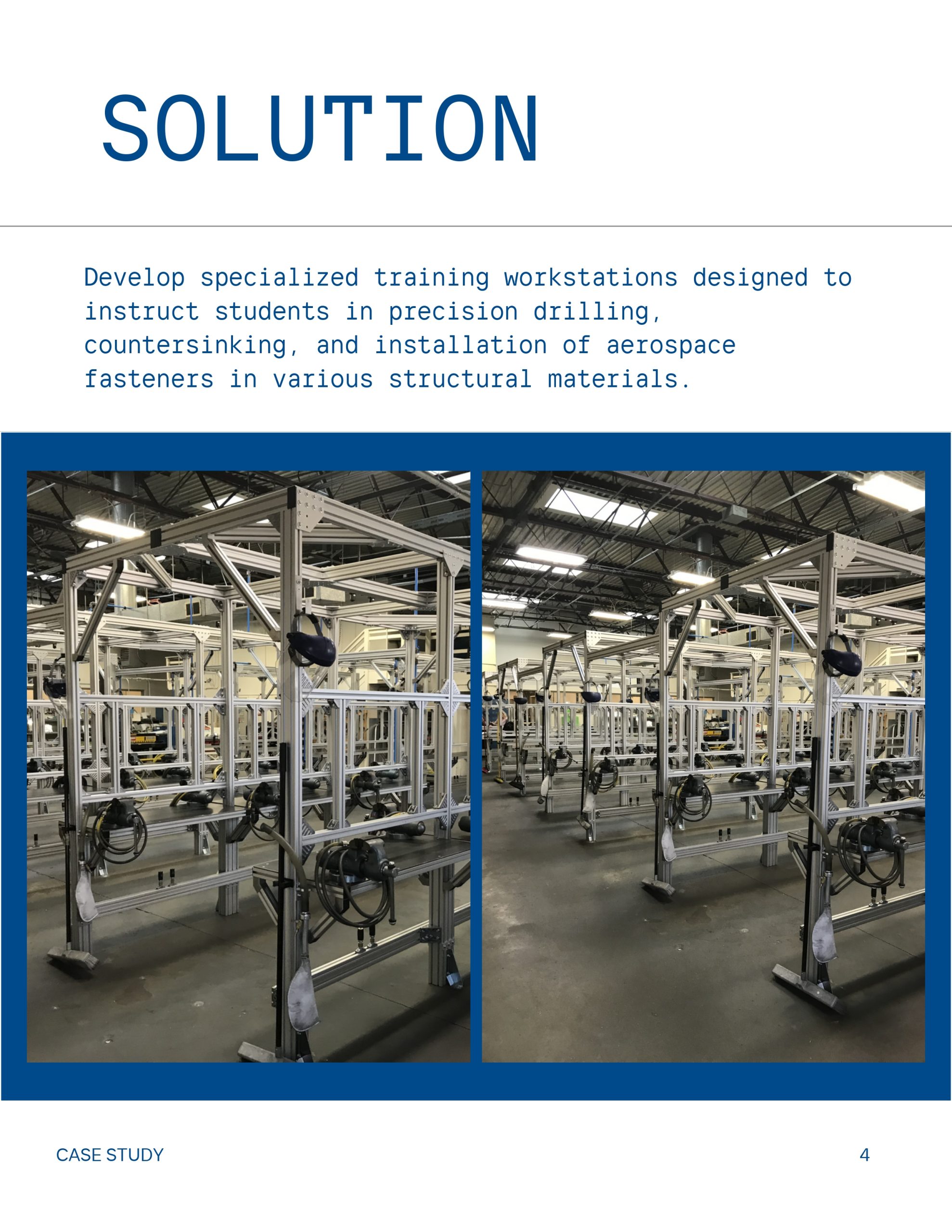

Solution

We leveraged Bosch Rexroth’s aluminum structural framing system to design and implement specialized training workstations. These workstations were customized to instruct students in precision drilling, countersinking, and the installation of aerospace fasteners in various structural materials. The solutions included ergonomic adjustments and the latest technological upgrades, ensuring that the training stations were both modern and flexible to meet WATR’s diverse needs.

Implementation Process

The implementation process involved close collaboration between WATR, Pacific Integrated Handling, and Bosch Rexroth. Based on WATR’s requirements, we developed customized training workstations that replicated Boeing’s Training Workstation System. We overcame design and manufacturing challenges through innovative engineering and the application of Rexroth aluminum framing, ensuring the workstations were ergonomic, technologically advanced, and capable of supporting demanding training needs.

Results Achieved

The custom training workstations led to a significant increase in student throughput in WATR’s programs, resulting in increased revenue for the center. The upgrades improved ergonomics, safety, and precision, aligning the training facilities with modern industry standards. The return on investment for these projects exceeded expectations, highlighting the success of the collaboration between WATR, us, and Bosch Rexroth.